K-Link

In 2016 Kohl’s seized the opportunity to launch an ambitious multi-year program called K-Link, which would move the item setup process to a newly created cloud platform where the customer and workflow would be at the center of the design.

the challenge

Kohl’s hadn’t updated the way they worked with Vendors to get products to the website in many years. Excel, email and an old mainframe were some of the systems the teams used.

Each team that managed their own product categories had their own processes and there was virtually no automated workflow which caused @$61mil a year loss in sales called OHNOS (on hand, not on sale).

To grow product (SKUs) required hiring additional resources, adding to the cost. This was no longer sustainable, we needed to find ways to automate portions of the workflow.

The design team was also brought in at the 11th hour to deliver wires based upon what product and engineering had already planned out, causing what seemed like little wiggle room in what we delivered or how to fit in research and testing.

I had to find ways to get the team the necessary tools and time to create the best possible outcome for the program.

top problems

18+ weeks to get products to the website

@ $61 million a year loss in sales due to lack of workflow

No consistent process and no workflow

To grow SKU count more resources needed

my role

Led a 4 person design and research team for this 4 year program.

Solved problems and kept design leadership up-to-date on status of program and any issues that would need their attention.

Worked with program owner to do 3 design audits to expose the issues where specs where not being followed.

Organized daily touch-basis with designers to ensure no one got siloed, for design reviews and share any potential issues.

Worked with leadership to purchase Abstract to solve for collaboration and file sharing for Sketch.

Strategized with Product and Business partners on long-term vision of K-Link and item setup for Kohl’s.

Helped organize a workshop to discover areas of opportunity to automate the process.

the solution

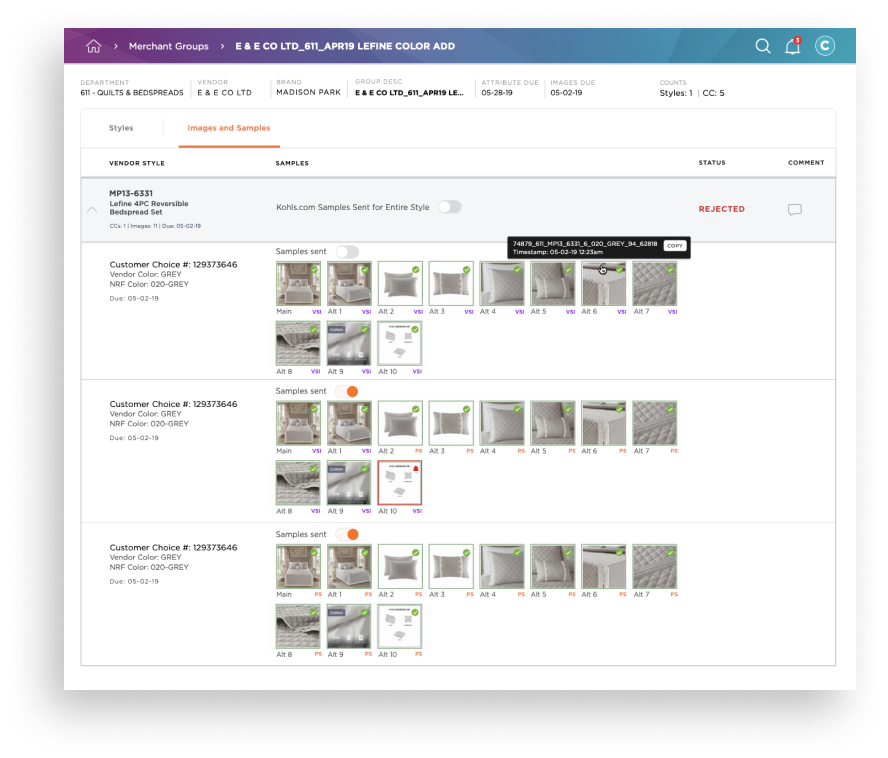

When we joined, it wasn’t quite clear how extensive this program would become. We were building a ground-up, cloud base tool to accommodate work that was previously done manually with excel and the help of an old mainframe called MDM.

process

This was the first internal tool that design worked on, so there weren’t established patterns. With the speed in which we needed to deliver, I made the decision to utilize Material Design. It was familiar and would let the designers focus on solving problems.

We were on two week sprint cycles, but to have designs signed off, my team had to deliver concepts within a week, this would leave time for business/product to review and for us to make updates.

To solve this, I encouraged the team to use Miro to have real-time collaboration with business. This allowed us to meet our deadlines and gain enough time for user testing.

Over the four years the team designed 1000s of wire-frames and created numerous flow documents.

Getting to know the users

This was the first time we worked with the Merchant team so, contextual inquiries were held with key members to discover their pain-points via Webex.

We needed to move fast and plan for future phases, we created multiple concepts, ran several rounds of testing until we landed on the first version.

concepts

I engaged our Brand team to help with final visual and styling. Dark blue header was phase 1 release. Multi color was final branding which came several months later.

Once the designs were settled on I assigned a designer to work with the Brand team to create Kohl’s first design system for internal applications. Because we had adopted Abstract with Sketch, we now had a way to create and manage a design system. This would allow the designers to move faster and more efficiently.

Today, Kohl’s works on multiple internal applications beyond K-link, such as Customer Service and Logistics, this design system has become the foundation for those programs.

Throughout the program, the design team held workshops with key stakeholders and to help visualize the user flows, we kept a process map.

This would help in identifying opportunities for automation.

conclusion

The team designed a completely cloud based application that allow merchants and vendors to set up items on Kohls.com more efficiently, where workflow is at the center.

“We expected to build a Ford, but you guys designed a Mercedes”

This allowed the merchant teams to think differently about how to get their jobs done. We also started to connect other systems to streamline the purchasing and selling of products on Kohls.com.

Over the course of my teams tenure on this program the key outcomes towards hitting the goals were:

Reduction in OHNO losses

Reduction in item setup time

Reduction in staffing needs